Data Card - Biomass, At the School of OpenCohesion & AzzerCO2

On February 16, 2005, the Kyoto Protocol entered into force, the first global agreement to combat climate change. It was published in December 1997, as part of the 3rd meeting of the United Nations Conference of the Parties on the climate (UNFCCC) and became operational following the signature made by 55 countries. On the occasion of the anniversary, OpenCoesione is publishing a Data Card dedicated at highlighting the result of the partnership signed in November 2019 between the Department for Cohesion Policies and AzzeroCO2, an organization that promotes environmental awareness campaigns, and focuses on several projects financed by cohesion policy and related to the energy production from biomass.

The collaboration was created to support the schools of At the School of OpenCohesion (ASOC) in assessing the CO2 emissions generated by the teams involved in the civic monitoring activities that take place during the year, with the subsequent offsetting of the emissions associated with the final event.

Due to the health emergency caused by Covid-19 and the suspension of all initiatives and activities offline, the calculation of emissions on the events of the 2020 Open Administration Week (SAA2020) was not carried out, while it was possible to carry it out for the final event of the 2019-2020 edition of ASOC held on 10 June 2020 and organized online in live streaming: in this case, the CO2 emissions relating to electricity consumption associated with the use of the PCs of the speakers and participants in the event were calculated, which were equal to 0.5 tons. ASOC has chosen to offset these emissions by purchasing 1 credit from the renewable energy production project from biomass for district heating in Valtellina

The project selected to mitigate emissions of 0.5 tons was developed by FIPER (Italian Federation of Energy Producers from Renewable Sources) and AzzeroCO2. The plant supplies electricity and heat in cogeneration to about 400 users through a district heating system, replacing the existing diesel generation with obvious benefits in terms of avoided CO2 emissions. The wood is used to provide the power to the plant and it comes entirely from the surrounding area and is made up of waste from sawmills and residues from forest maintenance and pruning.

What is the biomass?

In the general sense, "biomass" can be considered all material of organic origin, both vegetable and animal, intended for energy purposes or for the production of agricultural soil improver. To better outline this context, the three mainsectors that represent it can be considered: wood, agriculture, waste and waste processing. In the first case, wood produced from forests is used, in the second dedicated crops are planted while in the third one is used woodworking waste, agri-food industry waste and livestock manure. In the case of the project chosen by the ASOC team, the biomass is all from the local territory. The energy produced by these plants is considered a renewable energy source. Although the combustion process involves the emission of carbon dioxide (CO2), the DIRECTIVE (EU) 2018/2001 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 11 December 2018 on the promotion of the use of energy from renewable sources gives the evidence of the elements which help to understand why the use of biomass is considered virtuous in fighting against global warming. In particular, the annexes to the Directive report the percentage values of CO2 avoided thanks to the use of woody biomass, compared to the case of producing the same amount of energy from fossil fuel. A dossier edited by RSE (Research on the Energy System, research company of the GSE, Manager of Electricity Services, entirely controlled by the Ministry of Economy) shows how "in cases of use, for the production of electricity or heat, wood chips obtained from virgin wood, waste from wood processing and the wood industry with distances between place of origin and use of less than 500 km, the typical percentages of avoided CO2 vary between 89 and 94%. A little lower are the typical percentages of CO2 avoided in the case of cultivated woody biomass, at the same distance (between 83 and 91%). The percentages decrease for longer distances, remaining in any case higher than 84% for forest biomass with distances up to 2500 km ".

Cohesion policy and biomass

On the OpenCoesione portal we have identified some projects funded under cohesion policy which, like the project in Valtellina chosen by ASOC to offset for the final event of the 2019-20 edition, use local biomass to power remote heating projects . However, there are also innovative research projects working to understand how to use biomass.

DISTRICT HEATING SYSTEM AND VIRGIN BIOMASS CO-GENERATION CENTRAL AT THE SERVICE OF VILLA GUARDIA

In 2007, La Grande Stufa srl was founded in partnership composed by the municipal administration of Villa Guardia, the provincial federation of Coldiretti of Como and Lecco and the company Biocalore srl: La Grande Stufa was created to build and manage a co-generation and district heating plant in virgin biomass at the service of the town of Villa Guardia. In 2012, after a series of tests, “La Grande Stufa” was launched, providing the district heating service to around 240 public and private users. The plant, for the combined production of electricity (fed into the national grid) and district heating (intended for local users) works exclusively with "wood chips", that is wood reduced to small flakes coming from cleaning the woods, pruning and dedicated crops. A fundamental requirement for the wood that feeds the plant is its origin. The agricultural and forestry companies that supply the material (from 20 thousand to 40 thousand tons per year, for a value of between 700 and 900 thousand euros) are all located within a radius of less than 30 kilometers from the plant, thus providing timber "zero kilometer". The 2007-2013 programming period allowed the development of the idea of the environment industry through public-private participation, with the founding members with share capital divided in a balanced way. At the beginning of 2014, the opening to new shareholders (private citizens), further expanded the social asset and in 2015 La Grande Stufa became a joint stock company. The project is financed with 1.5 million euros in the framework of the ROP CRO ERDF LOMBARDIA Programme.

In 2007, La Grande Stufa srl was founded in partnership composed by the municipal administration of Villa Guardia, the provincial federation of Coldiretti of Como and Lecco and the company Biocalore srl: La Grande Stufa was created to build and manage a co-generation and district heating plant in virgin biomass at the service of the town of Villa Guardia. In 2012, after a series of tests, “La Grande Stufa” was launched, providing the district heating service to around 240 public and private users. The plant, for the combined production of electricity (fed into the national grid) and district heating (intended for local users) works exclusively with "wood chips", that is wood reduced to small flakes coming from cleaning the woods, pruning and dedicated crops. A fundamental requirement for the wood that feeds the plant is its origin. The agricultural and forestry companies that supply the material (from 20 thousand to 40 thousand tons per year, for a value of between 700 and 900 thousand euros) are all located within a radius of less than 30 kilometers from the plant, thus providing timber "zero kilometer". The 2007-2013 programming period allowed the development of the idea of the environment industry through public-private participation, with the founding members with share capital divided in a balanced way. At the beginning of 2014, the opening to new shareholders (private citizens), further expanded the social asset and in 2015 La Grande Stufa became a joint stock company. The project is financed with 1.5 million euros in the framework of the ROP CRO ERDF LOMBARDIA Programme.

In Farra D’Alpago, in the Belluno area, a biomass district heating plant has allowed the Municipality not only to reduce carbon dioxide emissions, but also to reduce energy costs by 30%. The investment, whose cost was approximately 770 thousand Euro, was financed by the ROP CRO ERDF Veneto 2007-2013 Programme. The district heating system has a capacity of 448 kilowatts and has replaced the old boilers powered by fossil fuels: inside two prefabricated buildings, eight variable modulation boilers consume beech and white fir pellets from the local wood supply chain, within which the municipality itself is located. The superheated water is transferred to the thermal power plant and stored in two 5,400-liter flywheels, ready to be distributed through the heating systems of the nursery, kindergarten, primary school, lower secondary school, Town Hall and the gym. Each phase is managed through a remote control system and monitored through PLC devices. In the summer, the biomass power plant is replaced by a 12 kilowatt solar system, sufficient to meet the energy needs and thus produce a further reduction in consumption.

was financed by the ROP CRO ERDF Veneto 2007-2013 Programme. The district heating system has a capacity of 448 kilowatts and has replaced the old boilers powered by fossil fuels: inside two prefabricated buildings, eight variable modulation boilers consume beech and white fir pellets from the local wood supply chain, within which the municipality itself is located. The superheated water is transferred to the thermal power plant and stored in two 5,400-liter flywheels, ready to be distributed through the heating systems of the nursery, kindergarten, primary school, lower secondary school, Town Hall and the gym. Each phase is managed through a remote control system and monitored through PLC devices. In the summer, the biomass power plant is replaced by a 12 kilowatt solar system, sufficient to meet the energy needs and thus produce a further reduction in consumption.

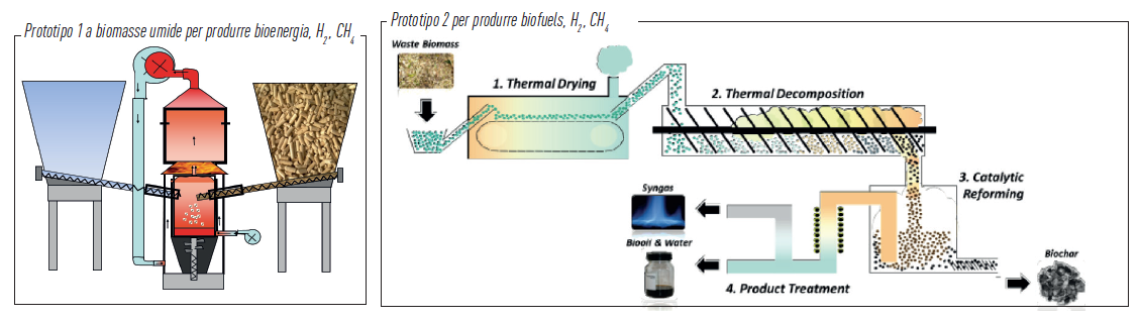

TERMOREF is a project financed by the ROP ERDF Emilia-Romagna 2014-2020 for an amount of over 1.3 million of Euro, which aims to transform biomass deriving from agricultural waste for the production of biofuels and biochar (charcoal). As part of the At the School of OpenCohesion project, the project was monitored by the ASOC1920 "Green Dreamers" team of the Liceo Classico Dante Alighieri in Ravenna. The choice of this project is the result of students' attraction related to the relationship between man

TERMOREF is a project financed by the ROP ERDF Emilia-Romagna 2014-2020 for an amount of over 1.3 million of Euro, which aims to transform biomass deriving from agricultural waste for the production of biofuels and biochar (charcoal). As part of the At the School of OpenCohesion project, the project was monitored by the ASOC1920 "Green Dreamers" team of the Liceo Classico Dante Alighieri in Ravenna. The choice of this project is the result of students' attraction related to the relationship between man and environment in the contemporary world, stimulated by the social movements that encourage the debate and which they analyse in class in the various disciplines of study. In addition, the project represents an opportunity for the city of Ravenna and for Emilia-Romagna given the agricultural nature of the territorial economy and the level of environmental pollution. The project sees as leader the University of Bologna and the participating companies IRIDENERGY Srl and SAUBER TEHNOLOGY SERVICES.

and environment in the contemporary world, stimulated by the social movements that encourage the debate and which they analyse in class in the various disciplines of study. In addition, the project represents an opportunity for the city of Ravenna and for Emilia-Romagna given the agricultural nature of the territorial economy and the level of environmental pollution. The project sees as leader the University of Bologna and the participating companies IRIDENERGY Srl and SAUBER TEHNOLOGY SERVICES.

Two prototypes were developed during the project:

-

the first is a pyrogasifier to which has been coupled a catalytic reforming capable of producing the synthesis gas which can then be valorised into hydrogen and methane with the addition of biochar at 20 to 30%;

-

the second prototype is capable of producing a liquid biofuel alongside a hydrogen-rich synthesis gas that can also be transformed into biomethane.

The team's creative paper is available here

The Monithon report is available here

BIOMASS ENERGY RECOVERY FLUVIAL BAYS (REBAF)

The REBAF project - Biomass Energy Recovery Riverbeds was funded by the ROP ERDF Emilia-Romagna 2014-2020 for a total amount of over 689 thousand euros. The leader of the initiative is the INTERMECH MORE interdepartmental center of the University of Modena and Reggio Emilia (Unimore). The main objective of the project is the modeling, construction and experimental validation of innovative systems and plants for the energy exploitation of woody and herbaceous biomass from the maintenance of the riverbed of the Secchia river. Also part of the consortium are CREA - Council for research in agriculture and analysis of the agricultural economy, CIDEA - Interdepartmental Center for Energy and the Environment of the University of Parma and CIRI-MAM - Interdepartmental Center for Industrial Research of advanced mechanics and materials of the University of Bologna. Floods represent a risk for all territories that are located in the vicinity of rivers. In order to prevent the risk, frequent maintenance of the embankments is advisable. A land of rivers and streams, the province of Modena must face the challenge of definitively securing its complex hydraulic node, making the banks safer, at the same time creating a virtuous, sustainable process with an interesting economic return. Then, take advantage of the large amount of biomass found both on the embankments and in the river beds (trees, grass, bushes and straws) available at no cost, to produce energy, while ensuring clear and safe embankments. Since biomasses are present in river areas of different types with different energy yields, researchers are working to build a prototype capable of transforming these different materials into biochar, the vegetable carbon obtained from the pyrolysis of different types of vegetable biomass. Many studies have already demonstrated the positive impact of the application of biochar on agricultural yields by decreasing the need for water and fertilizers. The biochar can be "returned" to the embankment to make it more fertile, alive and luxuriant and carry out physical storage of carbon in the soil.

amount of over 689 thousand euros. The leader of the initiative is the INTERMECH MORE interdepartmental center of the University of Modena and Reggio Emilia (Unimore). The main objective of the project is the modeling, construction and experimental validation of innovative systems and plants for the energy exploitation of woody and herbaceous biomass from the maintenance of the riverbed of the Secchia river. Also part of the consortium are CREA - Council for research in agriculture and analysis of the agricultural economy, CIDEA - Interdepartmental Center for Energy and the Environment of the University of Parma and CIRI-MAM - Interdepartmental Center for Industrial Research of advanced mechanics and materials of the University of Bologna. Floods represent a risk for all territories that are located in the vicinity of rivers. In order to prevent the risk, frequent maintenance of the embankments is advisable. A land of rivers and streams, the province of Modena must face the challenge of definitively securing its complex hydraulic node, making the banks safer, at the same time creating a virtuous, sustainable process with an interesting economic return. Then, take advantage of the large amount of biomass found both on the embankments and in the river beds (trees, grass, bushes and straws) available at no cost, to produce energy, while ensuring clear and safe embankments. Since biomasses are present in river areas of different types with different energy yields, researchers are working to build a prototype capable of transforming these different materials into biochar, the vegetable carbon obtained from the pyrolysis of different types of vegetable biomass. Many studies have already demonstrated the positive impact of the application of biochar on agricultural yields by decreasing the need for water and fertilizers. The biochar can be "returned" to the embankment to make it more fertile, alive and luxuriant and carry out physical storage of carbon in the soil.

ENTERRA - INDUSTRIAL DEVELOPMENT PROGRAM

The operation was financed by the investment of Enterra (a French-controlled company active in the energy sector) with 22.52 million Euro to which are added 26.34 million financed by the cohesion funds through the subsidies of the Development Agreement signed between Invitalia (the National Agency for the Attraction of Investments and Business Development) for a total of over 48 million. In particular, the “Development Contract” finances productive investment programs and related research and development programs in the industry, tourism and trade sectors. The operation involved the construction in Puglia, in the locality of Rignano Scalo near Foggia in the disused industrial area called "former Eridania sugar factory", of a new power plant fueled by biomass from the agro-industrial and agroforestry chain to produce electricity for nominal power of 13 MWe.

The operation was financed by the investment of Enterra (a French-controlled company active in the energy sector) with 22.52 million Euro to which are added 26.34 million financed by the cohesion funds through the subsidies of the Development Agreement signed between Invitalia (the National Agency for the Attraction of Investments and Business Development) for a total of over 48 million. In particular, the “Development Contract” finances productive investment programs and related research and development programs in the industry, tourism and trade sectors. The operation involved the construction in Puglia, in the locality of Rignano Scalo near Foggia in the disused industrial area called "former Eridania sugar factory", of a new power plant fueled by biomass from the agro-industrial and agroforestry chain to produce electricity for nominal power of 13 MWe.

The production of energy is obtained by means of a plant with a spreader stoker combustion system with the production of steam within a Rankine cycle. The power plant, powered by local plant biomass, uses part of the steam generated to power the thermal processes.

ASOC 2019-2020 AWARDS, biomass & AzzeroCO2

AzzeroCO2 helped the ASOC team assess the "energy cost" of the 2019-2020 online edition of the ASOC AWARDS. At the meeting there were about 800 participants connected on the Zoom platform, 31 were speakers and almost 1,400 views on the project's YouTube channel. The initiative allowed students to interact with institutional guests (like every year, but in a new way) and above all to bring out the results of their civic monitoring research. The AzzeroCO2 partner took into consideration the electricity consumption associated with the use of computers by the speakers and the rest of the participants. In detail, the following were considered:

-

electricity consumption associated with the use of a personal computer for the duration of the event (3 hours and 17 minutes) for remotely connected speakers;

-

the electricity consumption of the participants in the event.

It was therefore assumed that all users who took part in the final event followed the live broadcast for the entire duration (3 hours and 17 minutes) through their own personal computer. The calculation includes both the power consumption of the PC and the consumption of the data centers of the platforms used for streaming.

On the At the School of OpenCohesion website it is possible to consult an in-depth analysis of the calculation methodology created by AzzeroCO2!